A+ Balanced Flowmeters

Products

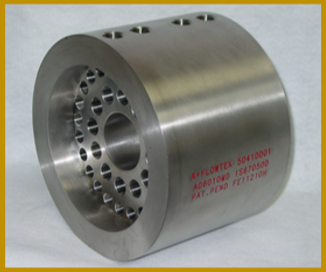

• Balanced Silencing Plate™

Benefits

a. ± 0.25% system* error; ± 0.15% plate* error

b. Repeatability > 99.99%

c. 1/2 diameter up/downstream allowable

d. <85 dB Noise, including RO’s, low cavitation/erosion

e. Uniform pipe velocity and pressure, conditioning

f. No harmful Eddies and vibrations, smooth ops

g. Over 10X life of single-hole thin plate

h. Designed for single or 2-phase flow, low cavitation index

i. Each plate custom designed for your unique process

j. Thousands of successful applications

k. 100% INCREASE IN PRESSURE RECOVERY

Solution

Balanced Flow Meter Issues

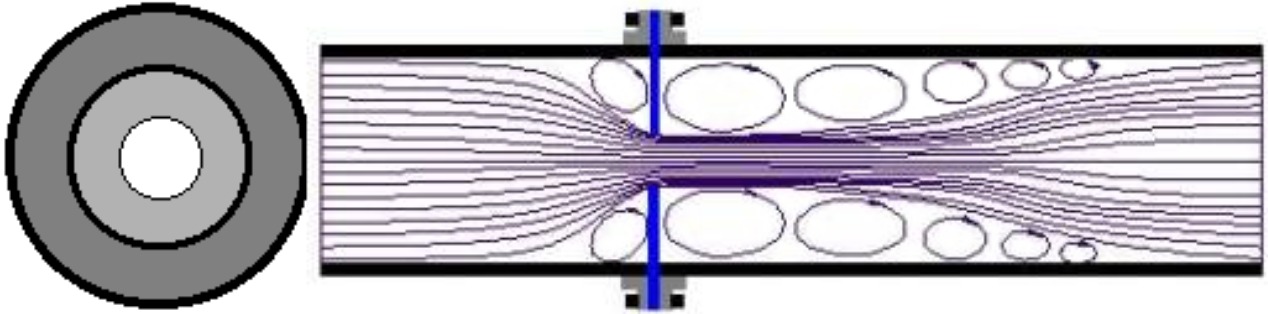

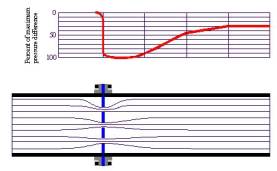

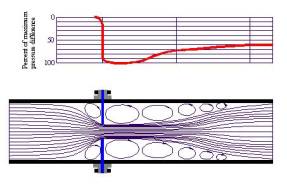

Current orifice meter technology is known to generate a large permanent loss of pressure. The pressure potential is consumed by the eddy turbulence. Accuracy lost is due to linearity and repeatability issues that are a direct result of the random and chaotic eddy turbulence formations.

Solution

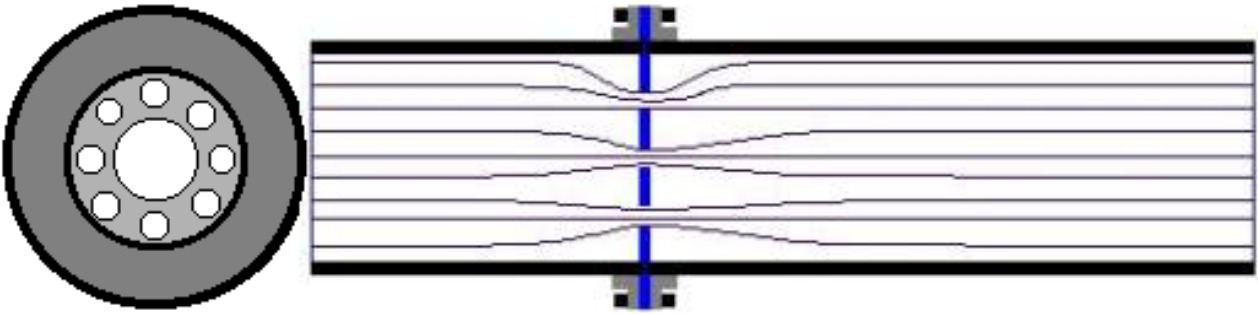

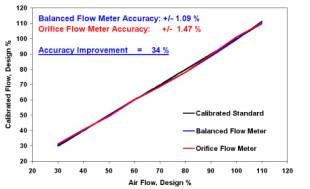

A+ FlowTek minimizes eddy's and provides higher accuracy over current orifice plate technology. With features worthy of a NASA patent, the A+ FlowTek’s Balanced Flow Meter has a 34% accuracy improvement and minimizes energy (pressure) loss by 50%. Accurate measurements are critical to improve plant operational efficiency. The difference between an accurate and an inaccurate flow reading can mean a significant cost savings. Additionally, lower pressure loss conserves energy and saves money.

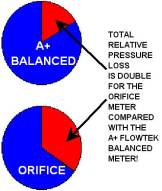

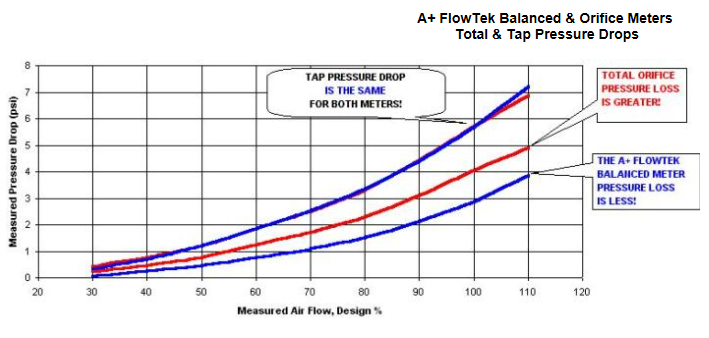

Pressure Loss

The A+ FlowTek

Balanced Flow Meter

provides a

50% reduction

in pressure loss,

saving substantial

energy costs.

Accuracy

BALANCED FLOW METER (BFM) ACCURACY

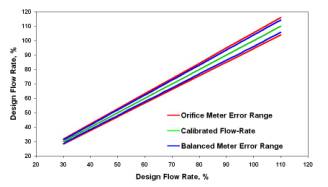

The eddy turbulence, generated by the orifice plate, interferes with the repeatability and linearity. The balanced meter increased reliability results in better flow measurement accuracy.

Repeatability - The A+ FlowTek Balanced Flow Meter provides a 54% repeatability (deviation) improvement, as compared to the standard orifice plate.

Linearity - The A+ FlowTek Balanced Flow Meter produces 34% improvement in overall accuracy (linearity), versus the standard orifice plate technology.

Note: These are pre-calibration accuracies. Post calibration accuracies are within 1/100,000.

Cost Savings

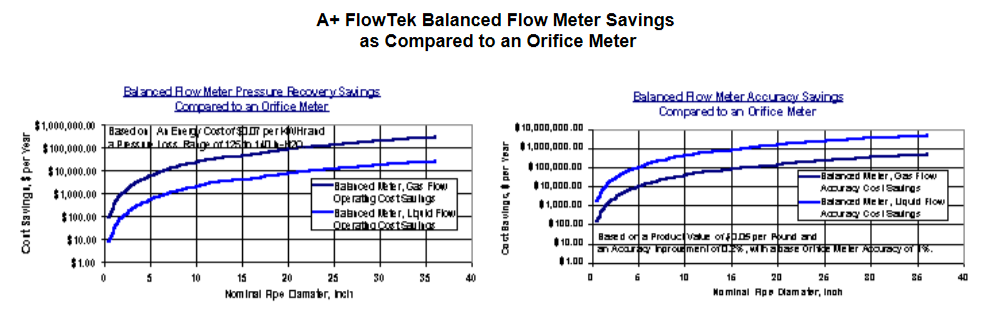

BALANCED FLOW METER (BFM) TOTAL COST SAVINGS

The payback period for replacing a standard orifice plate with the A+ Balanced Flow Meter plate is highly motivating. For typical sizes of 2 inches and more, based on total cost, the payback is no more than six (6) weeks. For incremental replacement costs, the payback is less than one week. With liquids, accuracy is more important than pumping costs. With gases, compression costs are comparable with accuracy costs. Energy cost savings alone make the A+ FlowTek’s Balanced Flow Meter preferable to the current orifice meter design. The estimated total accuracy and energy cost savings for gasses and liquids in many applications are shown below.

The cost benefits may vary dependent on the particular application. However, for any application, the A+ Balanced flow meter will provide superior performance over a standard orifice plate for accuracy, repeatability, rangeability, control-stability, quality, energy savings, and other improvements

LOW COST INSTALLATION

The A+ Balanced Flow Meter is competitively priced to the cost of standard orifice plates. Simply replace your current orifice plate with the A+ Balanced Flow Meter plate during normal maintenance cycles and start saving money through accuracy and energy cost improvements, while using all existing equipment. The A+ Balanced Flow Meter plate dimensions and fittings are the same as your existing orifice and the sensor differential pressure curves are equivalent. Additionally, your flow calculations will not need to be changed.

Benefits

BALANCED FLOW METER (BFM) BENEFITS

This new A+ FlowTek balanced metering technology provides many benefits when compared to orifice plate design.

- Reduced pressure loss

- Improved accuracy

- Enhanced repeatability

- Increased rangeability

- Self venting & Draining

- Lower vibration

- Reduced noise

- Straightens flow

- Cost effective

- Reduces pipe erosion

- Improved solids handling

- Direct orifice replacement

- No piping changes

- No instrumentation changes

- Same calculation method

- Reduced installation length

Piping Requirements

BALANCED FLOW METER (BFM) PIPING REQUIREMENTS

Recent NASA testing has successfully applied the Balanced Flow Meter without any straight run diameter requirements, either upstream or downstream. Elbows, tees, flanges, equipment, etc., can be connected directly to the Balanced Flow Meter with very successful results in all applications.

For severe applications in pumps, compressors, valves, etc., the impeller or valve seats are directly next to the plate.

The effects of fouling are minimum. Fouling with dense phase materials did not show an appreciable effect on performance. The fouling material passed directly through the plate without any build-up.

The flow range for this testing was from 5 percent of rated flow to over sonic flow conditions. Beta factors used in this NASA testing range from 0.25 to over 0.9 with various hole/area layout configurations. For all testing results, the Balanced Flow Meter out performed the standard orifice plate design in terms of accuracy, repeatability, noise and pressure recovery. The equations to be used with the Balanced Flow Meter plate are the standard venturi or orifice flow equations.

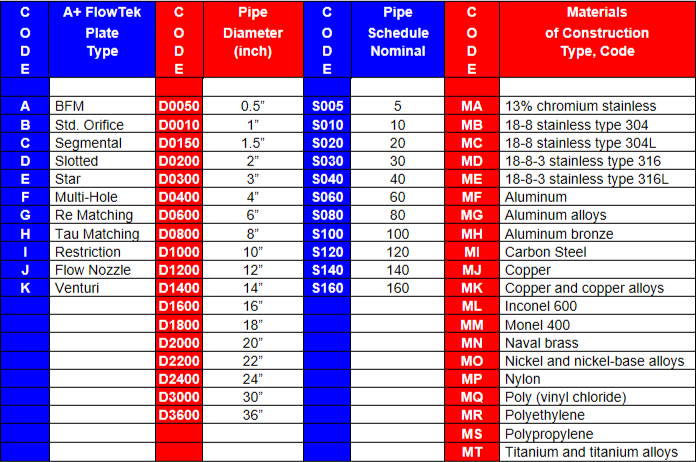

Product Chart

BALANCED FLOW METER (BFM) PRODUCT CODE CHART

The A+ Balanced Flow Meter is available with other A+ FlowTek meter designs to meet specific flow conditions and customer requirements. These designs include flow metering, critical flow, flow straightening, conditioning, mixing, and restriction orifices. For all gas and liquid flow measurements, the A+ Balanced Flow Meter is recommended for superior performance. Use the following A+ FlowTek Product Code Chart for flow meter selection and pricing specifications.

Product Code Example: A-D0400-S040ME:5000 product code is an A+ FlowTek Balanced Flow Meter (A) with a 4” (D0400), schedule 40 pipe (S040), made of 316L stainless steel (ME). The beta ratio code (5000) should be provided for complete plate specifications, in this example the beta ratio is 0.5000, (e.g. 1/2).